How To Make Candy Boards For Bees

past Anita Deeley at BeverlyBees.com

Winter has arrived and the girls are hungry! Time to brand a Candyboard for Winter feeding.

Buy a processed board frame hither!

In the midst of all my running around, cooking and baking for the holidays, the family members I could non however forget about were my bees.

In winter, honeybees consume much of the honey they work all spring and summer to produce. They form a cluster ball in the hive when the temperature gets cold and vibrate their bodies to warm up the bees inside. (Amazing, isn't it?) This takes a lot of energy which they get from honey consumption.

This winter has been milder than boilerplate, which I am loving, simply the warm temperatures are causing the bees to movement around more than normal. They proceed on doing the bee things they exercise during warm atmospheric condition instead of clustering for the winter. There is not much food for them to forage now and this increase in activity uses up more than of their stored dear than clustering. Since my hive was on the lower side of surplus beloved in the fall, I knew I had to feed the girls to help them get through the winter without starving to decease.

In the warmer atmospheric condition honey bees volition beverage sugar syrup, but the New England winters are much as well cold for that and other methods of feeding have to be used. Some people feed fondant or raw saccharide, some brand hard candy for the bees and others use candy boards. I found a not bad tutorial online from Southeastern Indiana Beekeepers Clan on making a candy board. Since this method did not require cooking the saccharide and making bodily processed, it seemed to be an easier method to attempt than other recipes I had seen.

My handy married man went to work making the 2 inch tall candy board frame from scraps of woods nosotros had lying around. He stapled 1/ii inch wire mesh to the inside for a candy support and drilled a 1/2″ pigsty in the front for the bees to escape. It came out perfect! Give thanks you, Brian! Yous can buy a processed board frame from our online shop if you lot don't have fourth dimension to make i yourself.

The Bee Candy Recipe called for

The Bee Candy Recipe called for

- 15-sixteen lb. of sugar*

- three cups water

- 1 tbsp. plain white vinegar (optional)

- i Pollen patty (optional)

*I have found that 16 lbs of sugar is as well much for my area in MA. I am cutting this recipe in half for 2012. For more data delight read Saccharide Candy Board Assessment.

First, I weighed out 16 pounds (yes xvi POUNDS) of saccharide and put it into in a very large canning pot. (I told you lot my girls were hungry!)  Next, I added the vinegar to the h2o and poured the water in a little at a time, stopping to make certain it was all mixed into the sugar.

Next, I added the vinegar to the h2o and poured the water in a little at a time, stopping to make certain it was all mixed into the sugar.

To mix it properly took some muscle only I still think this is easier and faster than cooking sugar processed on the stove.

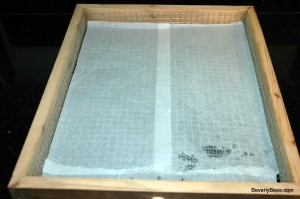

Next, I lined the wire mesh with paper that came with some beeswax foundation I had ordered for rolling candles. (For 2012 I will not be using this paper read why here.)

At present it was time to pile on the wet sugar. All the while, I was wondering when and if information technology would somewhen turn into a hard candy block.

Before more carbohydrate could exist added, I needed to cake out a department in the front of the board, below the entrance hole, to preclude information technology from filling up with sugar. This way the bees volition have a way to arrive and out of the lath. I stacked up 2 of my son's toy blocks for this purpose and they worked great.

When I reached the halfway point, I placed a pollen patty inside the center of the candy. The idea is that it will have several weeks for the bees to swallow enough saccharide to attain the pollen patty. The sugar below the pollen volition hopefully last them until the month of Feb when they will be running low on their own pollen stores and volition gladly welcome this one. The cold weather should deed as a natural fridge keeping the pollen fresh for them.  After the patty was securely in identify, I covered it with the rest of the sugar and leveled it off using a wooden ruler/pigment stick. Viola! At present I had a candy board waiting to dry.

After the patty was securely in identify, I covered it with the rest of the sugar and leveled it off using a wooden ruler/pigment stick. Viola! At present I had a candy board waiting to dry.

It took almost 24 hours for the candy to dry completely. This was a scrap of a pain in my small kitchen, during acme holiday baking time, when kitchen real manor is at a premium, just the bees are worth it! I removed the blocks carefully and to my amazement the processed was dry and hard every bit a brick.

It took almost 24 hours for the candy to dry completely. This was a scrap of a pain in my small kitchen, during acme holiday baking time, when kitchen real manor is at a premium, just the bees are worth it! I removed the blocks carefully and to my amazement the processed was dry and hard every bit a brick.

Once the board is made, (which for someone handy is very uncomplicated only for me would take forever) you can reuse it year after year. The processed was fairly easy to brand and I can see myself doing this once again. Although sixteen lbs of sugar seems like a lot, any sugar that is not used up can be made into carbohydrate syrup in the leap, then waste material not. Y'all can read about how to exercise that here.

At present information technology's off to the hive because my girls want candy!

Copyright © 2011-2019. Anita Deeley, BeverlyBees.com. All rights reserved.

To notice out how to install the candyboard please encounter Installing The Candy Lath For Winter Feeding. To observe out how the candyboard worked overall read Saccharide Candyboard Assessment.

If you do not want to brand a candy board, I have a limited number for auction for total size hives and nucs. Buy a candy board frame here!!!

Other Posts You May Bask:

- Installing The Candy Board For Wintertime Feeding

- The Bees Are Enjoying Their New Candy Lath

- Spring Candyboard Inspection

- Carbohydrate Processed Lath Cess For Feeding Bees in Winter

- Making Sugar Syrup From The Candy Board

Source: https://www.beverlybees.com/beginner-beekeepers-guide/i-want-candy-so-lets-make-a-candyboard-for-winter-feeding/

0 Response to "How To Make Candy Boards For Bees"

Post a Comment